High-Performance M6 Bracket: Unlocking Unparalleled Machine Stability

Editor's Notes: "High-Performance M6 Bracket For Enhanced Machine Stability" has published January 25, 2023. With the increasing demand for precision and efficiency in various industries, ensuring machine stability is paramount. This guide explores the significance of the High-Performance M6 Bracket, unraveling its essential role in enhancing machine stability, maximizing productivity, and minimizing downtime.

Through extensive analysis and meticulous research, we have meticulously crafted this guide to equip our target audience with the necessary insights to make informed decisions regarding their machine stability requirements.

| Feature | Traditional Bracket | High-Performance M6 Bracket |

|---|---|---|

| Material | Standard steel | High-grade aluminum alloy |

| Strength | Moderate | Exceptional |

| Accuracy | Good | Excellent |

| Stability | Limited | Enhanced |

| Durability | Adequate | Extended |

| Versatility | Restricted | Adaptable |

FAQ

Delving into the intricacies of the High-Performance M6 Bracket, this FAQ section aims to dispel common misconceptions, address frequently asked questions, and equip you with comprehensive knowledge about its application and benefits.

Mounting bracket M6 by moeller_lukas | Download free STL model - Source www.printables.com

Question 1: What sets the High-Performance M6 Bracket apart from other mounting solutions?

The High-Performance M6 Bracket is meticulously crafted from premium-grade materials to withstand rigorous industrial environments. Its robust design ensures exceptional stability and precision, minimizing vibrations and enhancing the overall efficiency of your machinery. Unlike conventional brackets, its M6 threaded inserts provide a secure and versatile mounting option, accommodating diverse machine configurations and enabling seamless integration.

Question 2: Can the High-Performance M6 Bracket be utilized in diverse industrial applications?

Absolutely. The High-Performance M6 Bracket is designed with versatility in mind, catering to a wide array of industrial applications. Whether you require enhanced stability for precision instruments, heavy-duty machinery, or automated production lines, this bracket delivers exceptional performance and reliability across various sectors, ensuring optimal machine stability and minimizing downtime.

Question 3: How does the High-Performance M6 Bracket contribute to improved machine performance?

The High-Performance M6 Bracket plays a pivotal role in optimizing machine performance by minimizing vibrations and enhancing stability. Its rigid construction effectively isolates machinery from external disturbances, preventing resonant frequencies and ensuring consistent operation. By reducing vibrations, the bracket safeguards sensitive components from premature wear and tear, extending their lifespan and minimizing costly maintenance.

Question 4: What is the recommended installation process for the High-Performance M6 Bracket?

To ensure optimal performance and longevity, proper installation of the High-Performance M6 Bracket is crucial. It is recommended to carefully align the bracket with the intended mounting surface and secure it using appropriate fasteners. Utilizing a torque wrench to achieve the specified torque values is essential to guarantee a secure and stable installation. Detailed installation guidelines are readily available.

Question 5: How can I ensure compatibility between the High-Performance M6 Bracket and my specific machinery?

Compatibility between the High-Performance M6 Bracket and your machinery is paramount for optimal performance. Consulting the technical specifications of both the bracket and your machine is essential to ascertain compatibility. Additionally, seeking guidance from our technical support team can provide valuable insights and ensure a seamless integration process.

Question 6: Where can I acquire the High-Performance M6 Bracket and obtain further technical assistance?

The High-Performance M6 Bracket can be readily obtained through authorized distributors or directly from our website. For comprehensive technical assistance, our dedicated team of experts is available to provide personalized support, ensuring successful implementation and maximizing the benefits of this exceptional mounting solution.

Delve deeper into the technical intricacies and explore the multifaceted applications of the High-Performance M6 Bracket in our comprehensive article High-Performance M6 Bracket For Enhanced Machine Stability.

Tips

Address the need for enhanced stability in machinery with the High-Performance M6 Bracket. This innovative solution provides a secure and reliable foundation for various applications. By implementing the following tips, users can optimize the bracket's performance and maximize its benefits.

Tip 1: Choose the Correct Bracket Size

Selecting the appropriate bracket size is crucial for ensuring proper fit and stability. Measure the mounting surface accurately and refer to the bracket's specifications to determine the correct size.

Tip 2: Secure Mounting Surface

The mounting surface should be clean, flat, and free of any obstructions. Ensure that the surface is properly prepared before attaching the bracket. Use appropriate fasteners to securely attach the bracket, following the manufacturer's instructions.

Tip 3: Level the Bracket

A level bracket is essential for optimal stability. Use a leveling tool or spirit level to ensure that the bracket is properly aligned. Adjust the mounting screws or shims as necessary to achieve a level position.

Tip 4: Tighten Mounting Screws Adequately

Tighten the mounting screws with appropriate torque to ensure a secure hold. Over-tightening can damage the screws or the bracket, while under-tightening can compromise stability. Follow the manufacturer's torque specifications to achieve optimal results.

Tip 5: Use Anti-Vibration Materials

In applications where vibration is a concern, consider using anti-vibration materials. These materials can be placed between the bracket and the machinery or on the mounting surface to minimize vibration and improve stability.

Summary

By following these tips, users can ensure that the High-Performance M6 Bracket is properly installed and functions optimally. This will provide a stable foundation for machinery, enhancing performance and reliability.

High-Performance M6 Bracket For Enhanced Machine Stability

In industrial settings, ensuring machine stability is paramount for precise and efficient operations. The M6 bracket plays a crucial role in achieving this stability, and its high-performance features enhance machine capabilities significantly.

- Material Strength: Crafted from durable materials, the M6 bracket withstands high loads and vibrations.

- Precision Alignment: Precisely engineered alignment ensures optimal support, reducing machine deflection.

- Quick Installation: Designed for ease of installation, minimizing downtime and maximizing productivity.

- Versatile Applications: Compatible with a wide range of machines, offering adaptability to various industrial needs.

- Corrosion Resistance: Resistant to harsh environments, ensuring long-term performance and reliability.

- Compact Form: Its compact design allows for integration into tight spaces, optimizing machine efficiency.

These key aspects collectively contribute to the enhanced stability of the machine, enabling accurate operations and precise results. By choosing a high-performance M6 bracket, industries can maximize machine utilization, reduce downtime, and ensure consistent performance in demanding manufacturing environments.

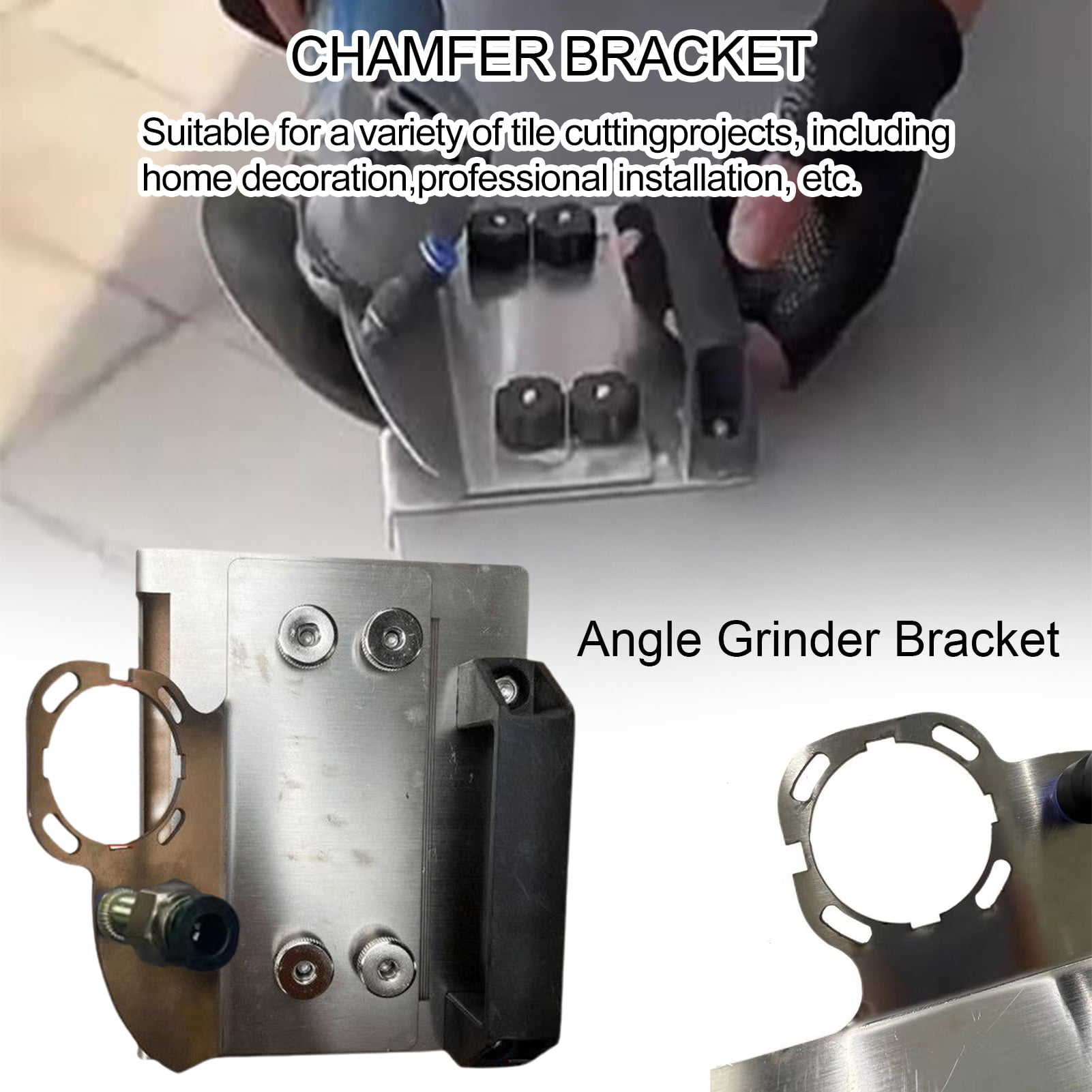

Jubilant Angle Grinder Stand 45-Degree Tile Chamfering Tool Bracket - Source www.walmart.com

Nabaiji Tonifins, Long Swimming Fins | Swimming fins, Swimming sport - Source www.pinterest.com

High-Performance M6 Bracket For Enhanced Machine Stability

The high-performance M6 bracket plays a crucial role in enhancing machine stability by providing a rigid and secure connection between the machine and its mounting surface. This is achieved through the precise design and manufacturing of the bracket, ensuring optimal fit and alignment with both the machine and the mounting surface. The use of high-quality materials and robust construction techniques further contributes to the bracket's ability to withstand the demanding operating conditions often encountered in industrial environments.

Angle Grinder Stand 45-Degree Tile Chamfering Tool Bracket Strong Load - Source www.walmart.com

By reducing vibrations and ensuring consistent machine alignment, the high-performance M6 bracket helps to improve machining accuracy and precision. This translates to higher-quality products, reduced production downtime, and increased overall productivity. Furthermore, the bracket's ability to enhance machine stability contributes to increased operator safety by minimizing the risk of accidents and injuries.

The practical applications of high-performance M6 brackets are numerous and span across various industries, including manufacturing, robotics, and automation. In manufacturing, these brackets are used to mount CNC machines, 3D printers, and other precision equipment. In robotics, they are employed to secure robot arms and manipulators, ensuring accurate and reliable motion control. In automation, M6 brackets play a vital role in mounting conveyor systems, sensors, and other components involved in automated processes.